Borrelly Ondufil Wave Springs

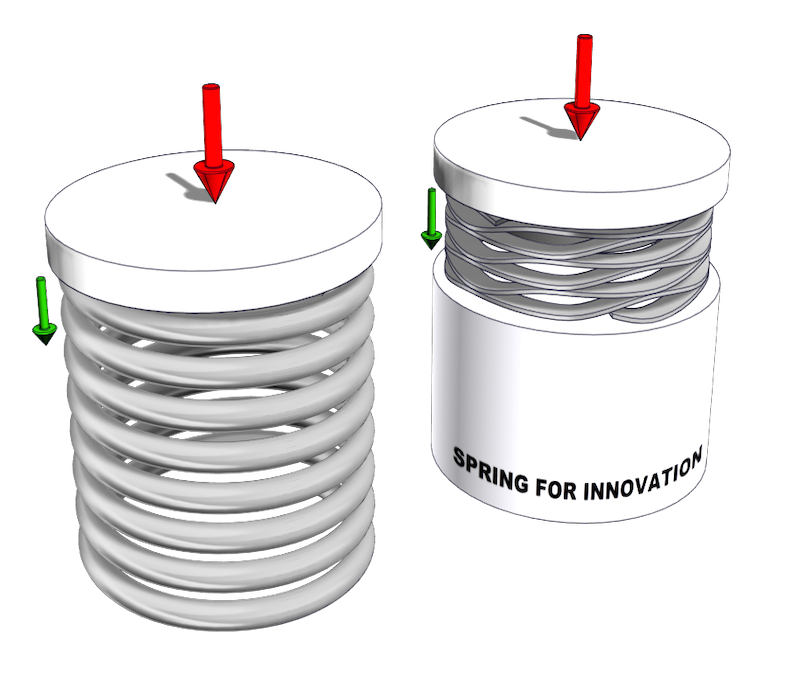

Compared to helical springs, Ondufil Wave Springs can handle the same loads but require less axial space to do so.

Thanks to this gain in axial space, the number of mechanisms of an assembly can be reduced significantly.

If a Borrelly wave washer is not delivering sufficient deflection, the Ondufil Wave Springs, by optimizing the number of active wave turns, gives a solution that is superior to a helical spring.

Standard range Ondufil

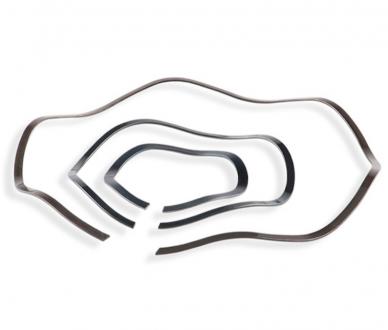

An Ondufil wave spring is a round elastic element taken from the same family as our Belleville or Diaphragm washers, resulting from a new manufacturing technology consisting in simultaneously rolling and corrugating a flat wire corresponding to the width of the coil.

Ondufil wave springs meet ever-increasing customer needs for more compact housings, greater deflections (as regards elastic deformation) and a greater variation in terms of spring rates.

Our Engineering & Design Department, using powerful calculation software, can respond quickly to your needs.

Our production workshop, fully integrated with production equipment designed and developed by Borrelly, can produce Ondufil wave springs from prototypes to very large runs.

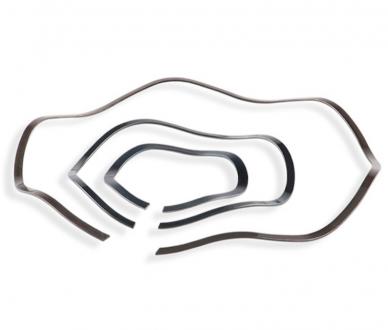

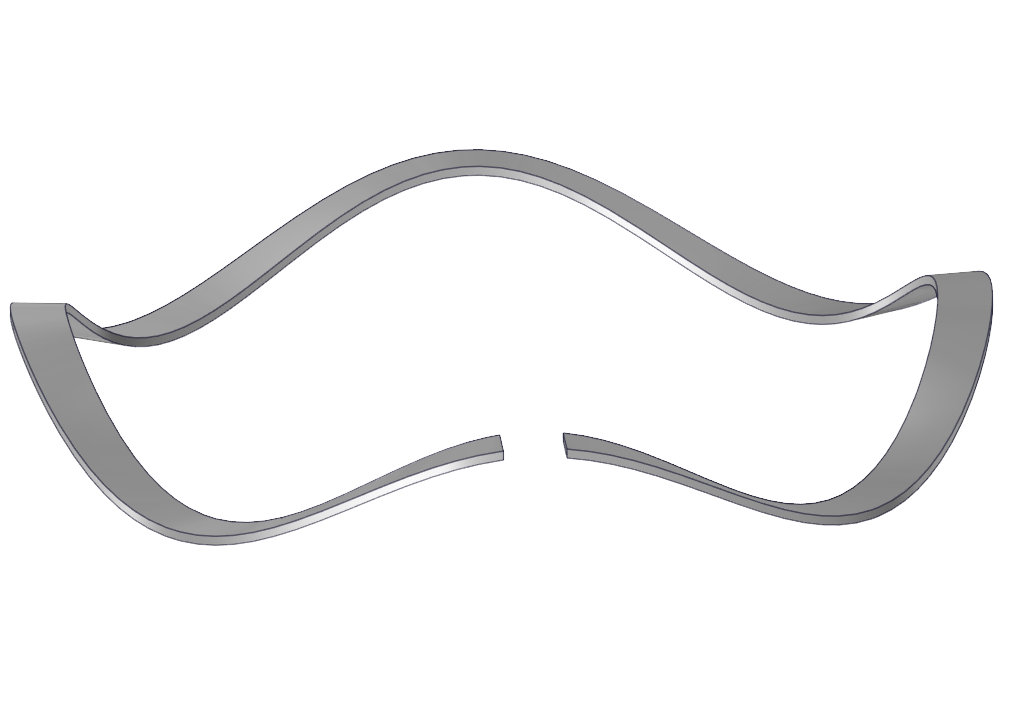

The different geometries of Borrelly Ondufil wave springs

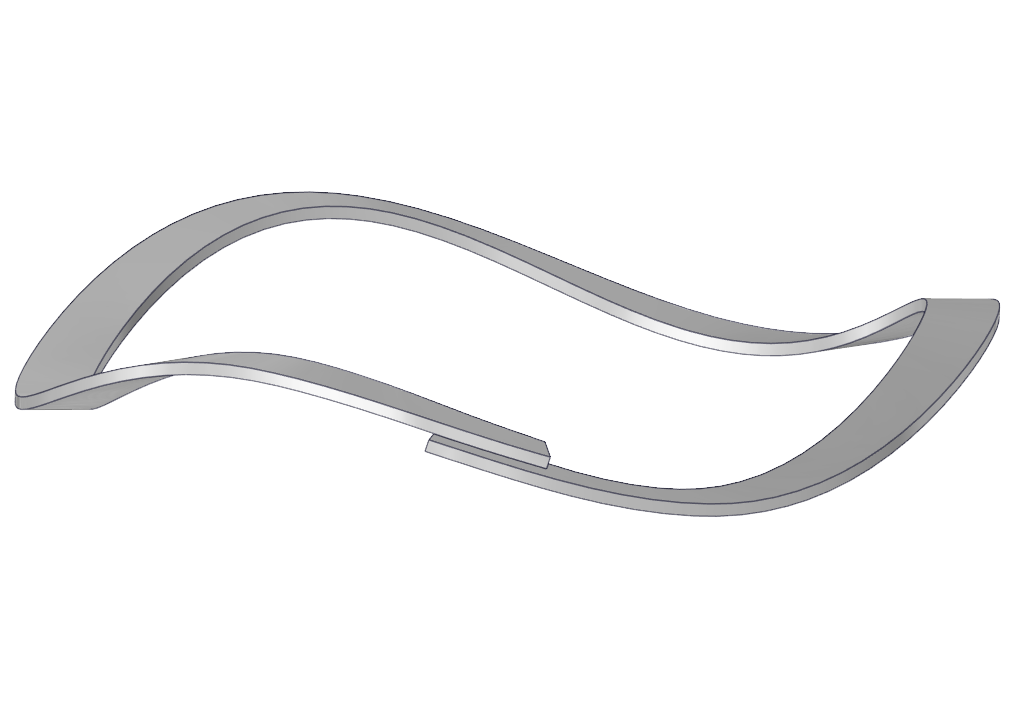

Borrelly Ondufil single-turn gap type: the Ondufil wave spring can be centred in a bore (even allowing a slight tightening).

Borrelly Ondufil single-turn overlap type: the Ondufil wave spring can be centred in a bore (even allowing a slight tightening). two thicknesses of material with respect to the Borrelly Ondufil gap type

Borrelly Ondufil single-turn overlap type: the Ondufil wave spring can be centred in a bore (even allowing a slight tightening). two thicknesses of material with respect to the Borrelly Ondufil gap type

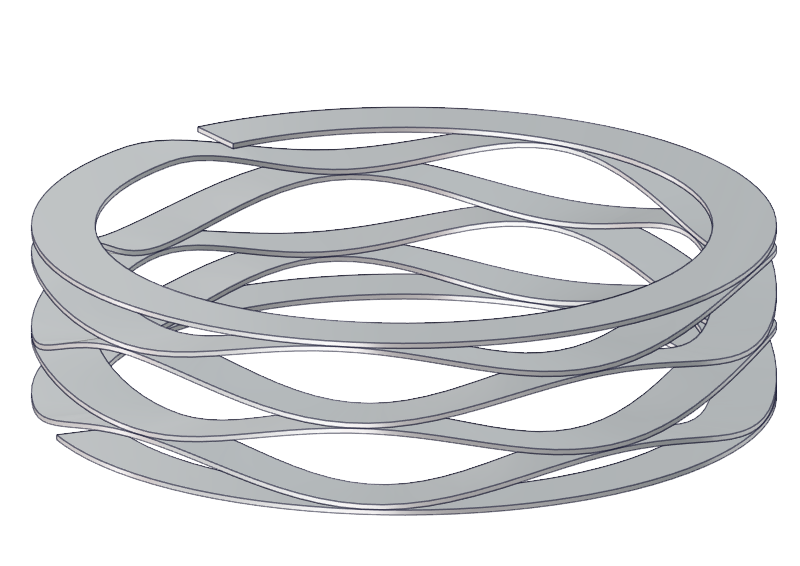

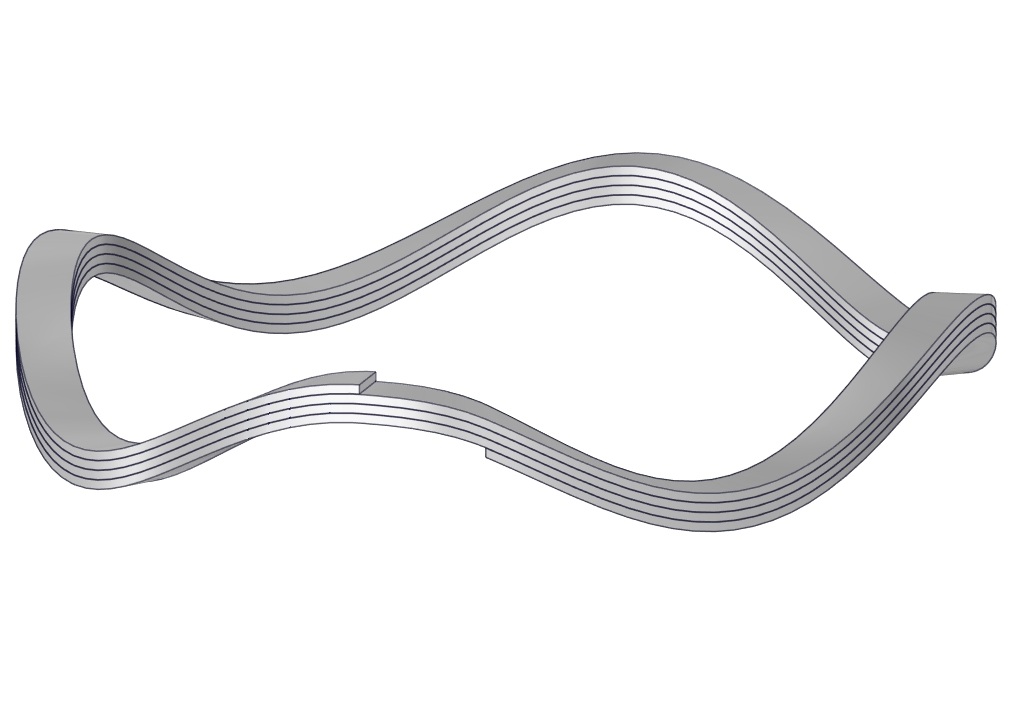

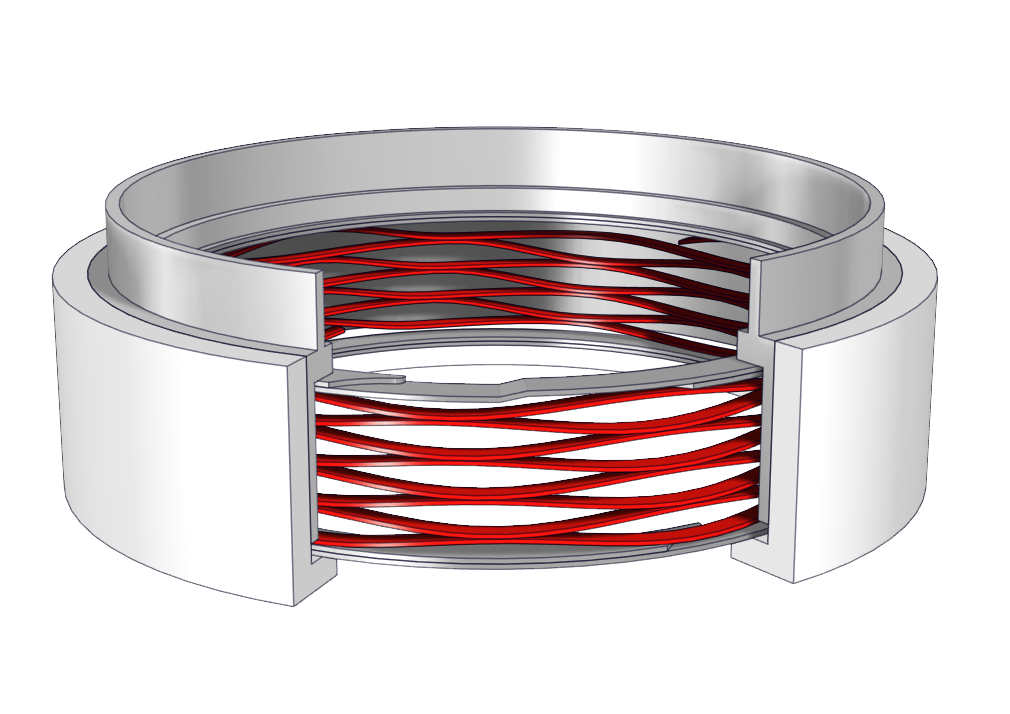

Borrelly Ondufil multi-turn wave springs: multiply the deflection of a wavy turn by the number of turns.

Borrelly Ondufil multi-turn wave springs with shim ends: multiply the deflection of a wavy turn by the number of turns. If shim ends are used, support rings are no longer required.

Borrelly Ondufil with interlocking (or parallel) turns: multiply the effort of one turn by the number of turns.

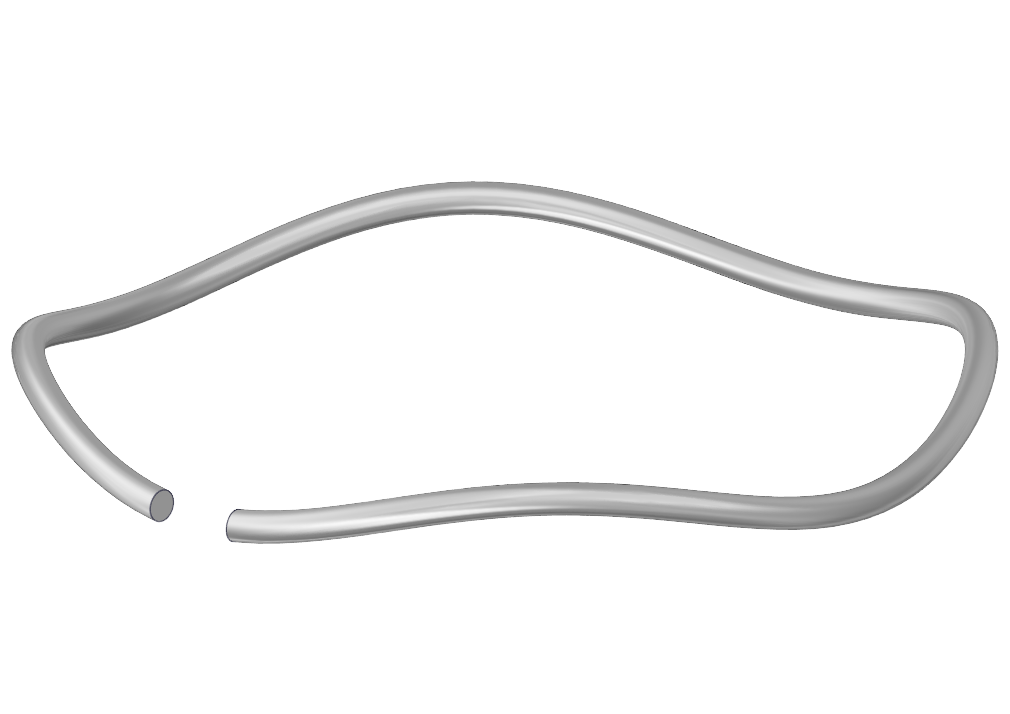

Borrelly Rondufil: Rondufil springs are made of round wire: can handle higher loads than single-turn Ondufil wave springs.

Assembling a Borrelly Ondufil wave springs

The open coil of a single-turn Borrelly Ondufil wave spring, of gap or overlap type, allows us to centre the washer along the bore (even allowing a slight tightening). Its diameters do not vary regardless of the crushing height.

In the case of a Borrelly Ondufil wave spring with several inverted or overlapping turns, centring can be done either along the shaft or bore. Please consult us for the clearances to be provided during assembly.

Sample applications for Borrelly Ondufil wave springs

|

|

|

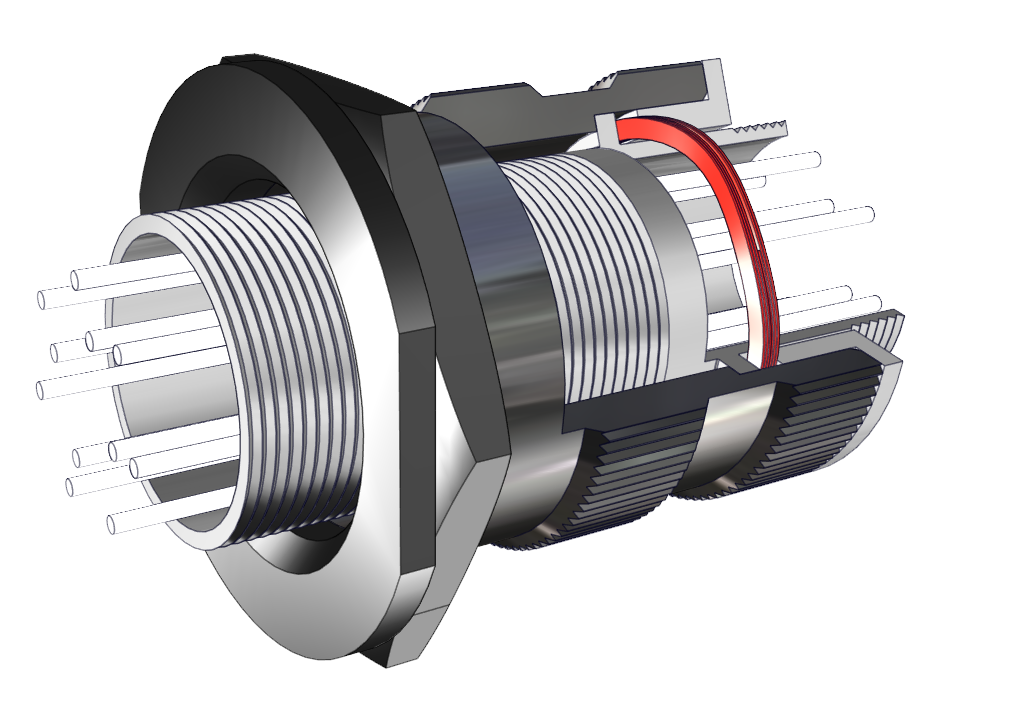

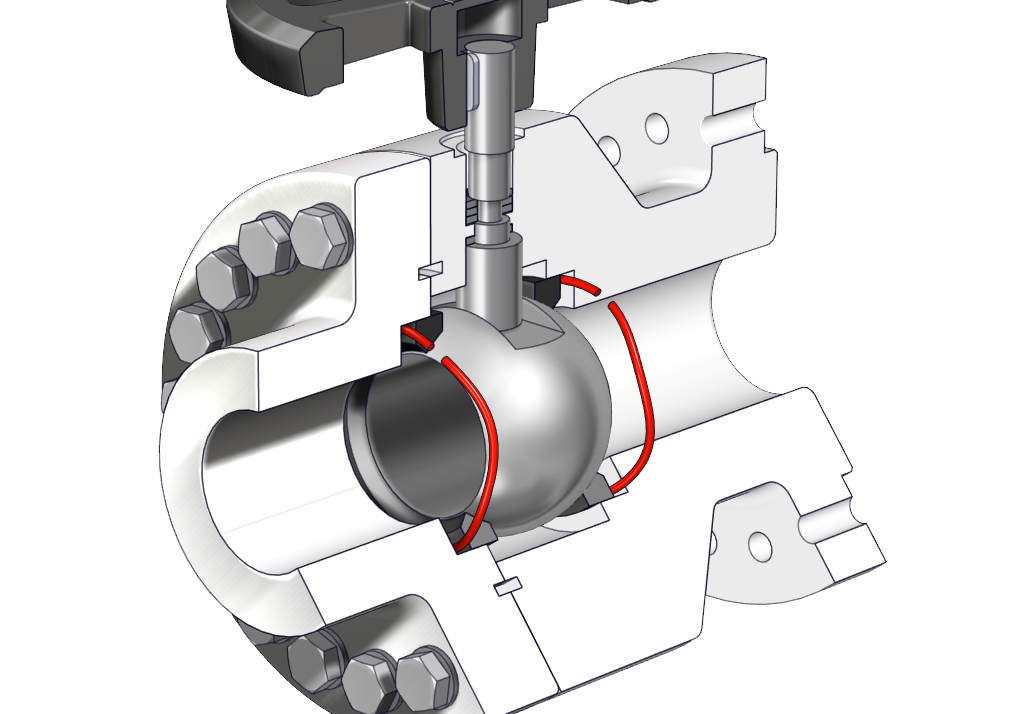

| Ondufil connector | Ball valve |

Mechanical sealing |

Materials frequently used in our Ondufil wave springs

XC75 steel (1.1242)

Stainless steel:

- AISI 301 : 1.4310

- AISI 302 : 1.4310

- AISI 316 L : 1.4404

- AISI 316 TI : 1.4571

- 17-7PH : 1.4568

Special applications:

- CuBe2 : 2.1247

- INCONEL 718 : 2.4668

- INCONEL X750 : 2.4669

- INCONEL 625 : 2.4856

- Alloy A286 : 1.4980

- Uranus B6 (1.4539)

- Hastelloy C4

- Hastelloy C276 2.4819

- Alloy 20 CB3 (2.4660)

- NIMONIC 90 : 2.4969 ou 2.4632

- René 41 (2.4973)

- SAF 2507 (1.4410)

- SAF 2205 (1.4462)

Our Engineering & Design Department can help you choose the material best suited to your application.

COMPLIANCE

99,8 %

RELIABILITY

95,9 %

SERVICE

48 H