Our catalog of spring washers

Like all springs, spring washers are calculated by applying classical theories of material strength. Calculations are used to determine the value of forces and stresses as per deformations.

Provided that the starting hypotheses are properly chosen, these calculations are accurate and correspond closely with experimentally controlled measurements.

Borrelly’s engineers bring all their know-how to bear by studying problematic issues on a case-by-case basis, and propose standard, precision and customized solutions based on studies of linear or non-linear static behaviours with large finite-element displacements.

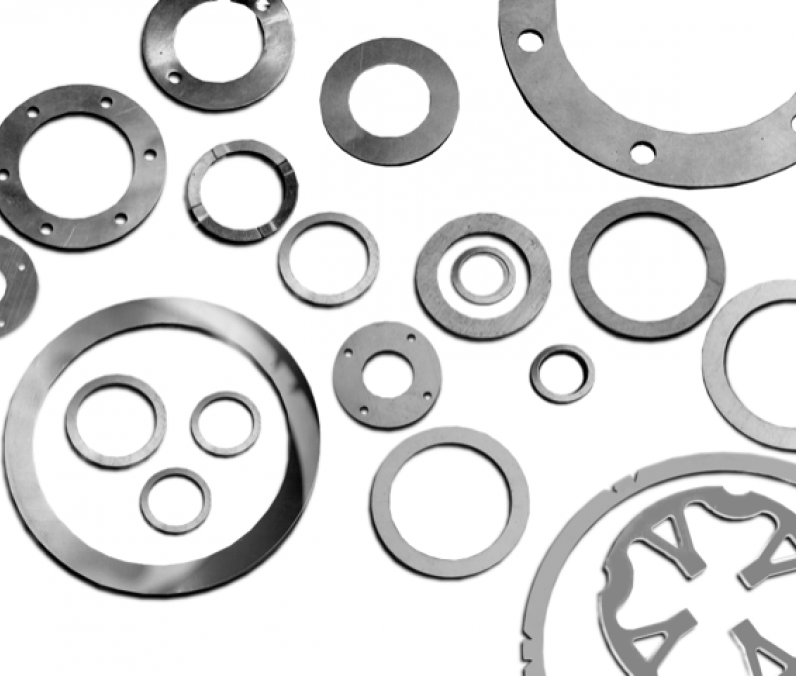

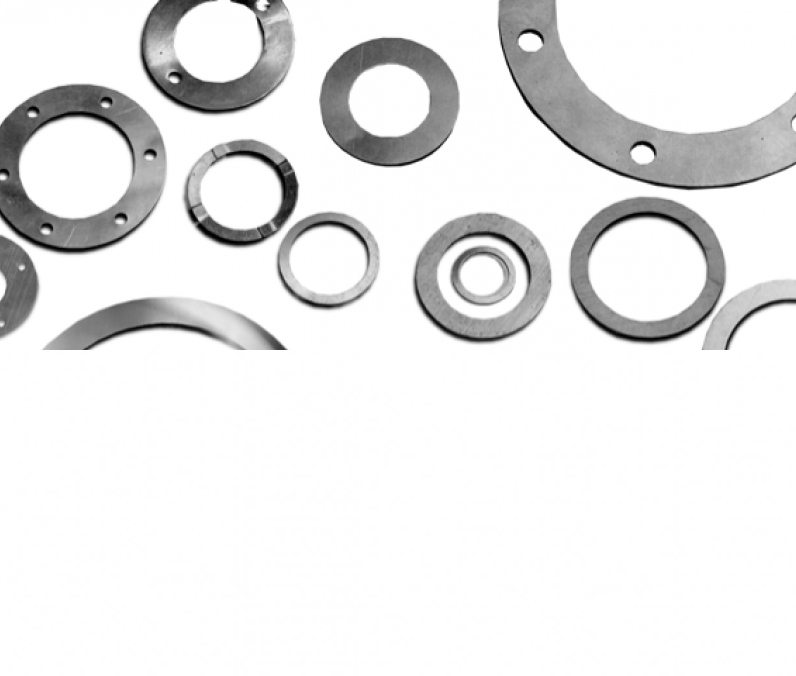

Like coiled wire springs (e.g., coil springs), spring washers are round elastic elements. In contrast to the former, which are “high” in relation to their diameter, spring washers are “low” in relation to their diameter.

A spring washer should therefore be used when a “round spring element” is to be used in an assembly and when axial space (rather than radial space) is available. The use of space along a diameter rather than height-wise is generally advantageous; it is one of the best ways to store: the most “elastic” force per unit of volume.

Spring washers can be classified into several families :

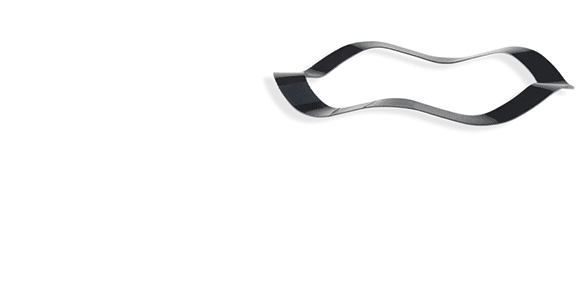

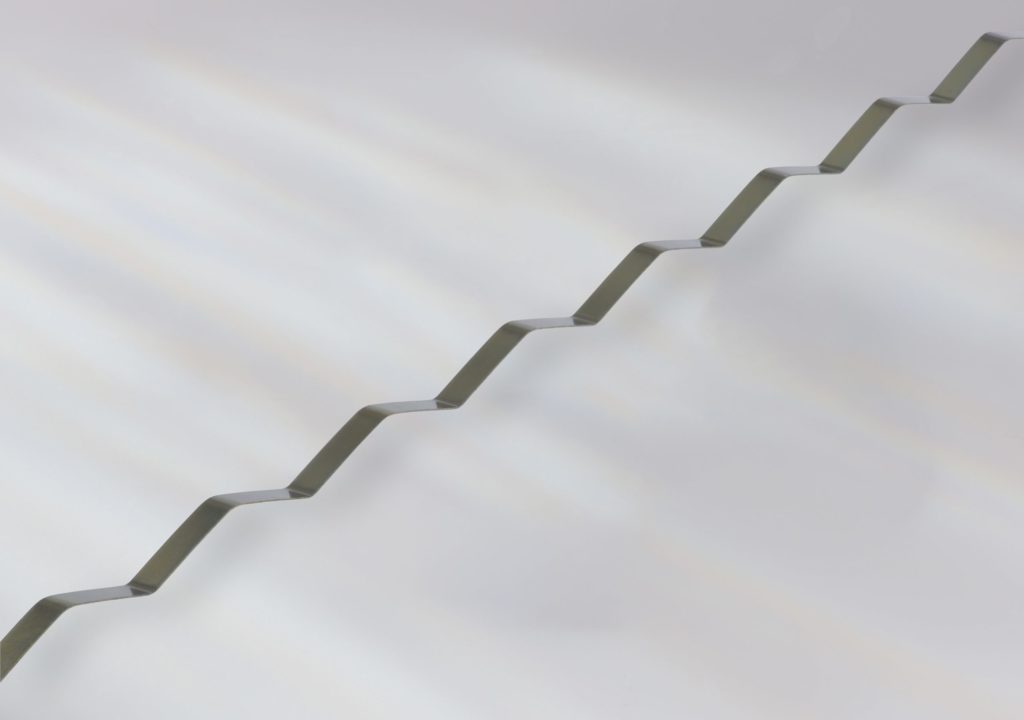

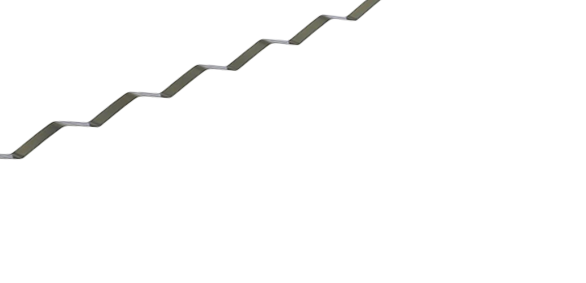

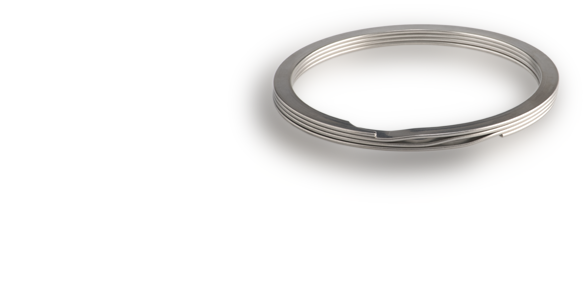

- Wave washers : designed and developed by the Borrelly family, this type of spring washers is commonly used to compensate for the internal clearance of ball bearings.

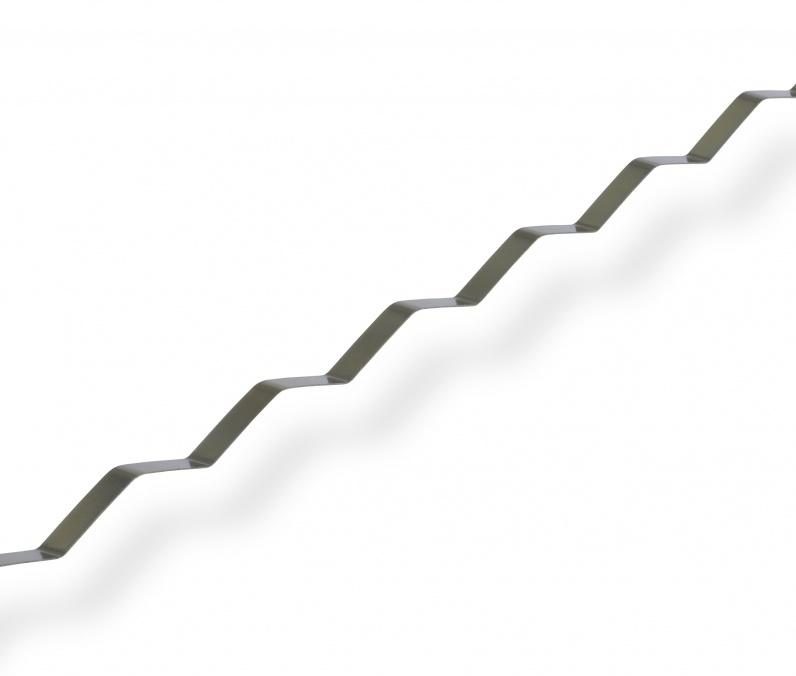

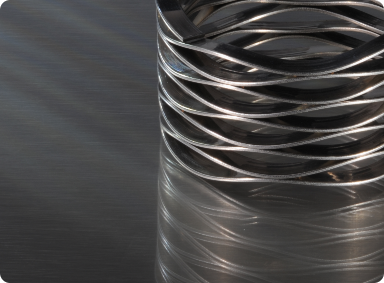

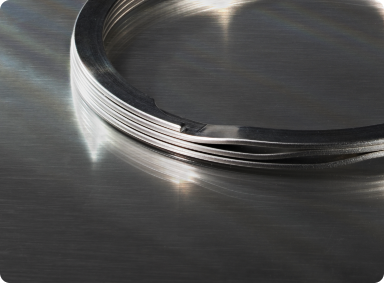

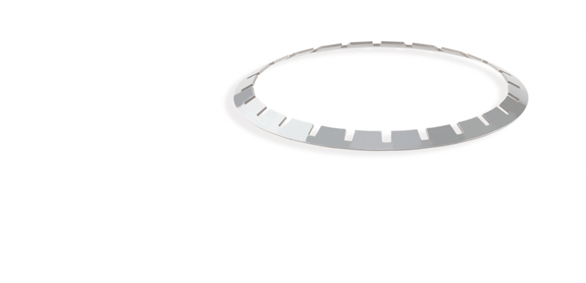

- Wave springs : this type of spring washers is manufactured by simultaneously rolling and corrugating a flat wire. They can be of different types : single-turn gap or overlap wave springs, with interlocking turns, multiturn, with or without shim ends…

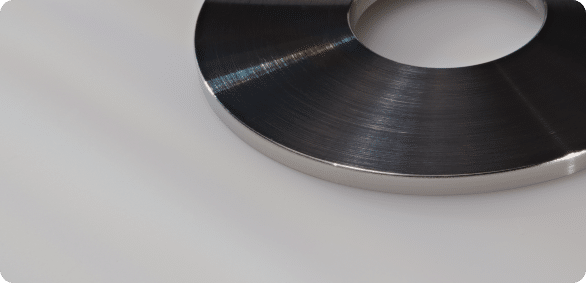

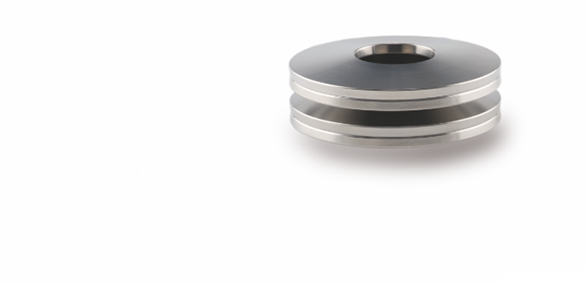

- Belleville-type spring washers : conically-shaped, Belleville disc springs are known for their ability to support heavy loads in small spaces. They can be used singly or stacked.

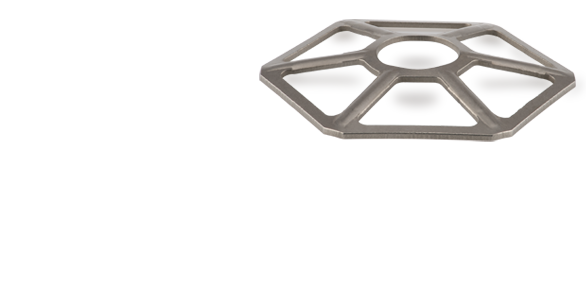

- Diaphragm-type spring washers: those special case of Belleville-type washers can deliver a wide range of elasticity curves and handle very large loads. They can also be used as a multi-turn spring.

Our spring washers are commonly manufactured in carbon steel as well as austenitic and structurally hardened stainless steel. For precise applications, our spring washers can also be manufactured in Inconel, Hastelloy, Beryllium Copper, Duplex, Super Duplex…

Spring washers are used in various sectors of activity (aeronautics, automotive, aerospace, defence, nuclear, motor sports, mechanical engineering, off-shore, medical, household appliances…) and cases of applications (flight instruments, steering columns, turbines, satellites, guidance systems, safety and oil valves, medical tools…).

The range of geometries available: Borrelly wave washer – Borrelly Ondufil® wave spring – Borrelly Diaphragm washer – Borrelly Belleville disc spring – Borrelly ROB® allow the material to be subjected to bending, torsion and shear stress.

The combination of the various stresses according to deformation results in forces that are not necessarily proportional to the displacements; this means that the elasticity curve can be adapted exactly to the required stress.

We use very-high performance materials; thus, our custom washers are fit-for-use in even the most severe environments, from cryogenics to high-temperature settings.

Design request

We study your needs to design your spring washers.

Our 90 years of expertise have enabled us to design and develop numerous ranges of high-quality technical standard products. Discover our wide range of references, generally available from stock.

Sectors of application

- Renewable energies

- Motorsports

- Agricultural industry

- Mechanical industry

- Pharmaceutical industry

- Consumer goods

- Green transport

Precision ranges are manufactured under our EN 9100 quality management system. Our products are available one week after receipt of your order.

Sectors of application

- Aeronautics

- Aerospace

- Automotive

- Defense

- Medical

- Nuclear

Thanks to our experience and know-how, our in-house design office can solve the most demanding problems in high-tech sectors, from prototype to mass production.

Sectors of application

- Aeronautics

- Aerospace

- Agricultural industry

- Automotive

- Consumer goods

- Defense

- Green transport

- Mechanical industry

- Medical

- Motorsports

- Nuclear

- Oil and Gas

- Pharmaceutical industry

- Renewable energies