Aeronautics

Borrelly Spring Washers is a historical supplier of aircraft washers for the aviation industry. For over 50 years, we have been designing and manufacturing flight instrument washers for the largest contractors in the sector.

Our experience allows us to collaborate with the engineering departments of our customers to study, design and manufacture the aircraft spring washer that will meet the most extreme technical requirements of the aviation industry.

The organization of our quality management system, the traceability of our products, and the repeatability of our processes all enable us to supply aviation quality parts. These are designed and manufactured in accordance with the NF EN 9100 standard, for which we were certified in June 2004.

We also have an in-house DPRV (Delegated Product Release Verification) agent, certified according to the AS9117 standard by SAE International as of May 2019.

For the aviation industry, our OTD (On-Time Delivery) performance is higher than 98%

For the aviation industry, our OQD (On-Quality Delivery) performance is at 100% based on the latest customer ratings

In 2017, we received the Best Supplier Award from our client Souriau-Sunbank Interconnect Technologies, Eaton Group.

We design and manufacture aircraft spring washers for the following aviation industry applications :

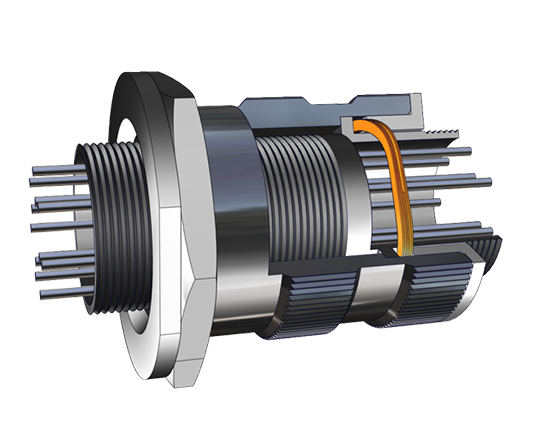

Multi-pin connectors

Each year, we manufacture several million spring washers for multi-pin connectors.

Fuel system

From take-off to landing, powerful computers are constantly activating various fuel flow pumps. This fuel supply allows the engines to provide sufficient power at all times while preserving the balance of the aircraft around its axes.

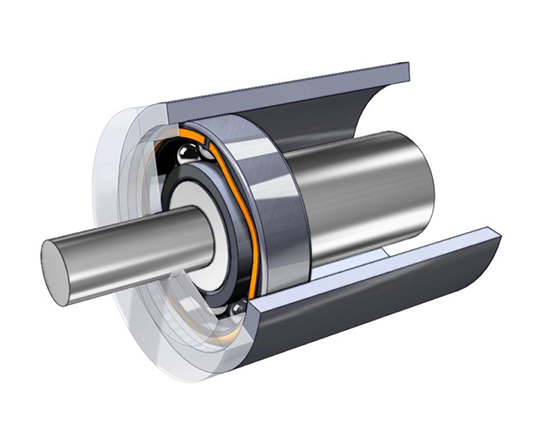

For over fifty years, we have been designing and manufacturing prestressing spring washers with the specifications to ensure perfect operation of these pumps. Most of our aircraft washers are used for the prestressing of fuel flow pump bearings

For both ground and in-flight equipment, Borrelly is a supplier historically valued by customers for its competence in the design and manufacture of very high quality aircraft washers with very quick turnaround.

Flight controls

Flight controls make it possible to map the pilots’ gestures to the mechanisms required for the desired action.

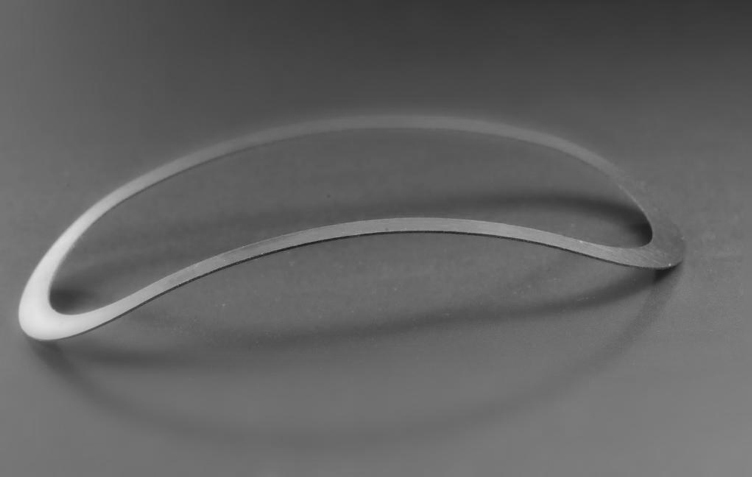

The reliability of these mechanisms is critical. Borrelly is therefore involved in the design and serial production of return springs, prestressing springs, clearance compensation springs, etc. This elastic blade, made from structurally hardened stainless steel, is housed in a reduced space and ensures the return of various flight control organs.

These elastic rings, used linearly or radially around a ball bearing, also contribute to clearance compensation, and can work as return springs or prestressing springs for flight control mechanisms. Our aircraft washers are entirely designed by our engineering department, according to our customers requirements, and manufactured from engineered materials with very high mechanical properties

Air circulation

Air quality in an airliner is a real challenge. Outside air is transferred to the cabin and conditioned for ventilation, thus keeping passengers and crew in a safe, healthy and comfortable space. Air circulation systems are very complex and must meet the strict rules of the Federal Aviation Administration and/or the certification specifications of the European Aviation Safety Agency.

Borrelly Spring Washers is a certified supplier of disc springs for civil aviation. We offer pre-cooler dampening washers, prestressing valve washers, bearing preload washers on fan motors, etc.

Clearance compensation linked to operating temperature constraints

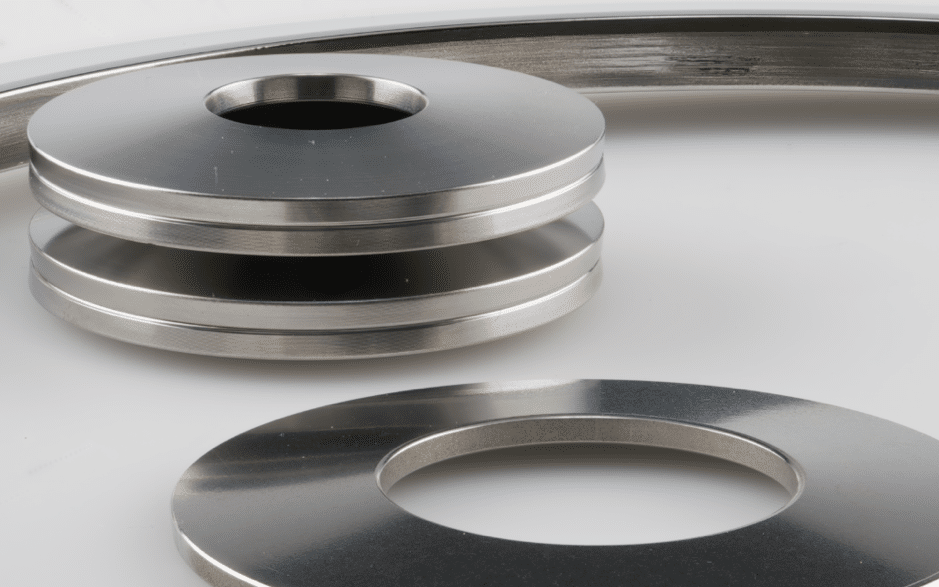

Ondufil® multiturn spring washer manufactured from Inconel 718:

In-flight equipment is exposed to variations between low and high temperature while in operation. The differential expansion of materials causes variations in tolerance intervals that our washers compensate for. In this context, our Ondufil® multiturn spring washer is used in an air treatment mechanism.

Browse our product catalog to find the right washer for your product.

Need more information? Contact us, we’ll be happy to respond.