Automotive

The automotive industry brings together the design, manufacturing and marketing activities surrounding passenger and heavy-duty vehicles.

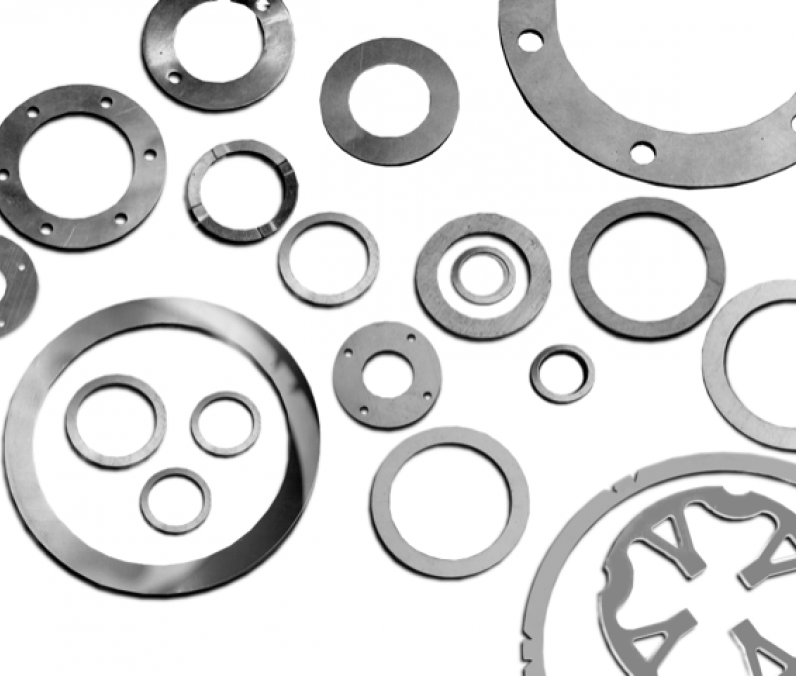

Since the 1970s, Borrelly Spring Washers has been a key player in automotive washers, spring washers being widely used as mechanical components in this sector.

Our engineering department collaborated with the largest contractors in the design and manufacture of automotive washers as prototypes and serially produced parts. These diaphragm spring washers are used for:

- Clutch mechanisms

- Creating artificial inertia in gearboxes

- Controlling vibration in steering columns

- Airbag release mechanisms

- Moving seat mechanisms

- Multi-pin connectors in wiring harnesses

- Compensating for differential expansion of turbocharger components

- Prestressing of water pumps

- Starter motors

- Prestressing of thermostatic valves, which allows fast preheating of engines and, therefore, of pollution control systems.

- For the past ten years or so, the automotive sector has undergone technological change, brought about by the transformation of engine and assistance units.

The elimination of hydraulic-assist components gives way to electrical units for which prestressing spring washers in ball bearings are used to their full potential.

Substituting a combustion engine for a hybrid or 100% electric motor requires a lot of spring washers.

Consequently, since 2012, Borrelly Spring Washers has become an essential partner to some of the largest contractors in the automotive industry.

Thanks to the reactivity and ingenuity of its personnel, and to its fully automated Industry 4.0 operations, Borrelly Spring Washers positions itself as a first-rank supplier to the leading international high-end automotive manufacturers.

In line with the certifications of its biggest customers in this sector, Borrelly Spring Washers is now on the verge of being able to claim International Automotive Task Force certification: IATF 16949:2016, automotive sector. This certification complies with the quality management system standard applicable to organizations for serial and spare parts production in the automotive industry.

We manufacture over 10 million spring washers per year.

Each washer is individually inspected, by checking all key features in a fully automated process, in order to guarantee that each part we deliver meets customer expectations.

We design and manufacture spring washers for the following automotive applications:

Radial clearance compensation in power steering rack electric motor bearings

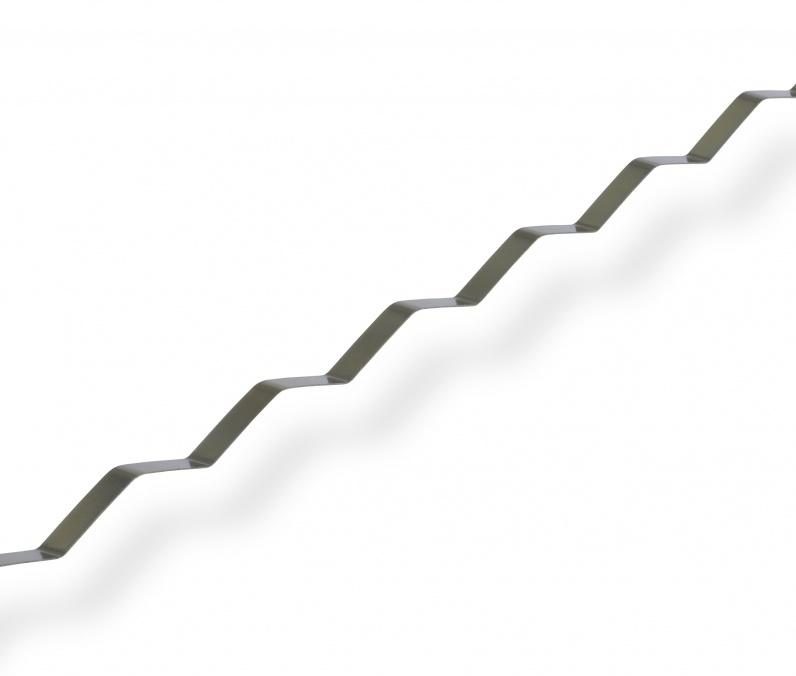

The differential expansion of the bearing housing resulted in clearance inside the bearing, causing vibration felt in the steering wheel by the driver. Manufacturing processes and quality control were thoroughly studied and perfected by Borrelly Spring Washers, in order to provide an automotive washer capable of taking up the radial clearance in the power steering rack electric motor bearings. Marketed as a mass-produced component, this ribbon spring is now fitted in high-end vehicles.

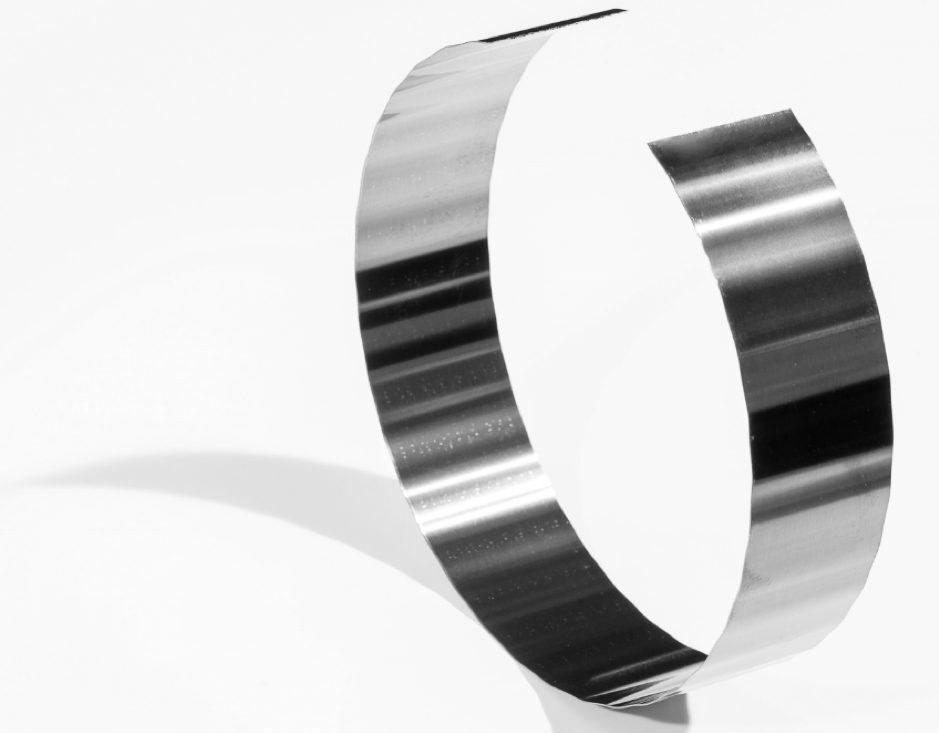

Axial preloading of power steering rack electric motor bearings

Developed by our engineering department, then tested and validated through road tests for over two years, this automotive washer ensures the preloading of ball bearings in power steering rack electric motors. Manufactured in millions of units nowadays, this part is used in very high-end passenger vehicles produced by an automaker for which we have been a leading supplier for many years.

Prestressing of thermostatic valve

Controlling the rate at which an internal combustion engine warms up has become essential to ensure the efficiency of anti-pollution devices. For that reason, we offer automotive washers designed specifically to address this issue.

Our Ondufil® multiturn wave springs are widely used by leading car manufacturers and OEMs that produce these pollution control systems.

BROWSE OUR PRODUCT CATALOG TO FIND THE RIGHT WASHER FOR YOUR PRODUCT.

Need more information? Contact us, we’ll be happy to respond.