Borrelly Ribbon Springs

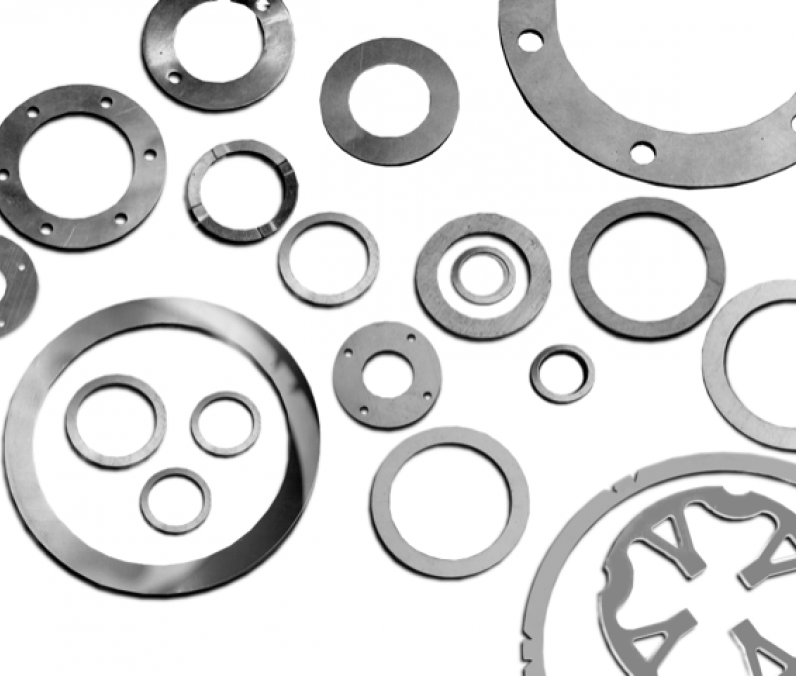

Spring rings are waved spring bands designed to control the clearance between the bearing and its housing.

Borrelly offers elastic rings for ball bearings in a wide range of materials, including Inconel, Phynox and CuBe2.

Technical description

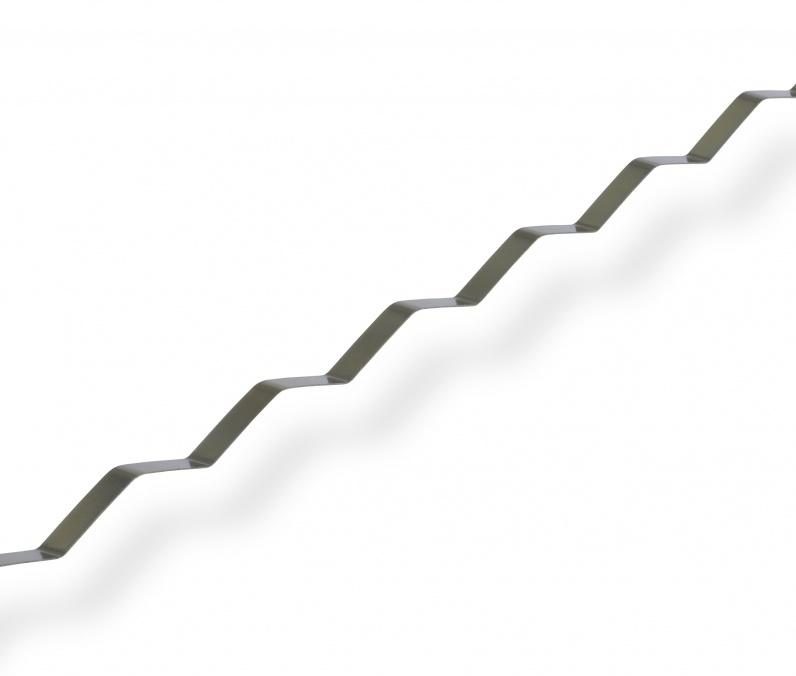

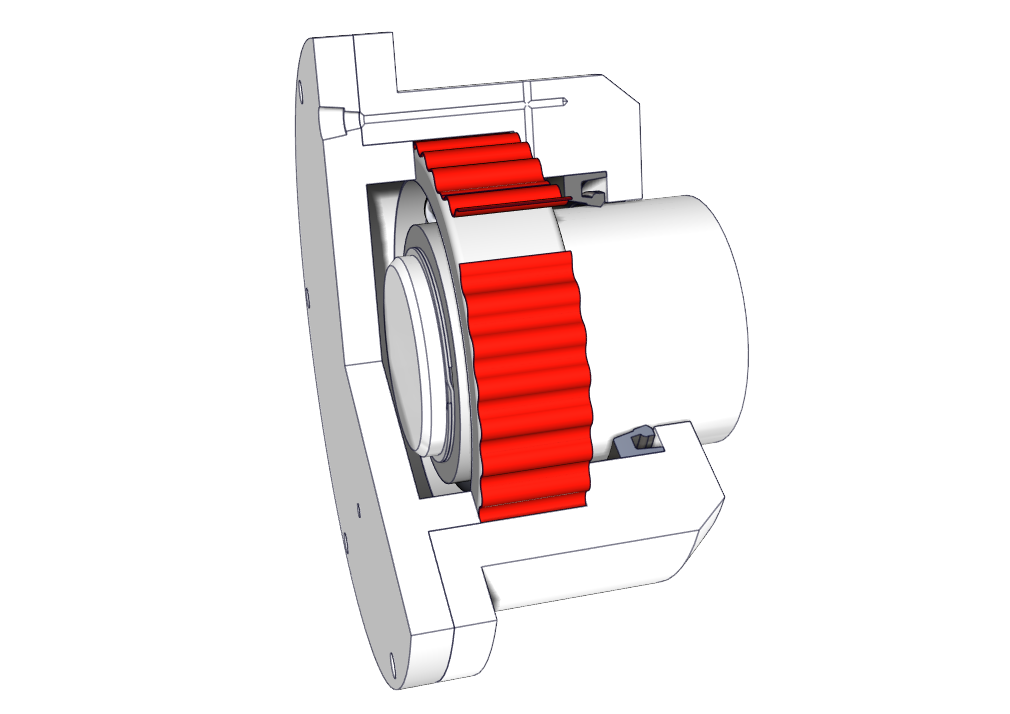

A ribbon spring is a continuous wave-formed sheet mounted between a bearing and its housing. The role of a ribbon spring is to permanently monitor clearance between bearings and their housing.

When assembled, the ribbon spring is preloaded and the bearing moves in the radial direction only if the preload force is exceeded.

The wave-formed sheet is designed so that the preload is at least equal to the load. Therefore the ribbon spring must not bend during operation, or the bearing has been incorrectly sized. If accidental radial overloads occur, the bearing is well able to support them since the ribbon spring acts as a shock absorber.

With ribbon springs, bearing housings can be machined with much larger tolerances without this compromising the quality of the fit.

- Ribbon springs can compensate for slight misalignments of housing.

- Since the clearance between the bearing and its housing is constantly monitored, there is no danger of the bearing “coming loose” (even in a light alloy).

- With ribbon springs, we can repair housings in which bearings have become “loose” without any filler metal.

- With a ribbon spring, the bearings are not set and thus can move axially to follow the dilation of the shaft.

- They can compensate for differential dilations that create harmful clearances between a bearing and its bore.

Borrelly has a broad and deep experience in the use of ribbon springs, and we can provide you with cost-effective solutions from the prototype to very large runs.

- High rotation speed (over 8000 rpm approx.): the inner or outer rings of a ball bearing are never perfectly cylindrical; they are cylindrical when first manufactured, and then, due to internal stresses, they become slightly deformed. If the bearing has to rotate very quickly, this deformation is detrimental to its service life and the bearing must be “rubbed” by its housing in order to return to a round form; however, the radial force exerted by a ribbon spring is never sufficient to properly rub the bearing.

- Vertical axis operation: Since bearings are subject to vibration, care must be taken to limit the space left for the ribbon spring in the axial direction. If this precaution is not taken, there is a risk of the ribbon spring coming loose from its housing during operation. This is similar to that which occurs in feeder-bowls used to dispense spare parts. In most such cases, the ribbon spring of the lowest bearing comes loose of its housing as it moves along a helical path.

99.8 %

Compliance

96 %

Reliability

48 h

Service