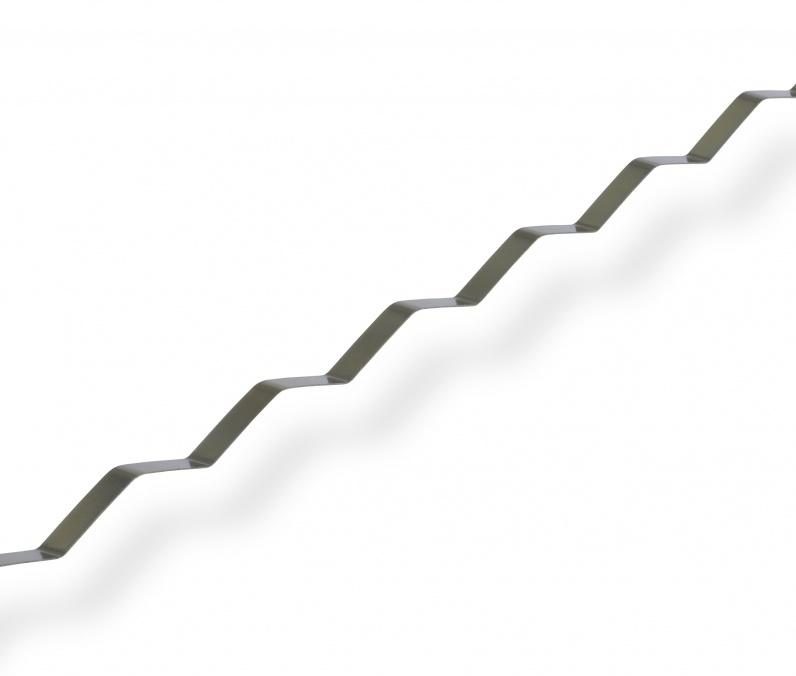

Borrelly Wave Washers

The Wave Washers was created and developed by the Borrelly family.

Today, thanks to its reputation, and peerless manufacturing quality, Borrelly has become a widely appreciated industry reference over the years. As a result, the wave washer is better known as the “Borrelly Wave Washers”. One of the most common applications is the preloading of ball bearings.

Technical description

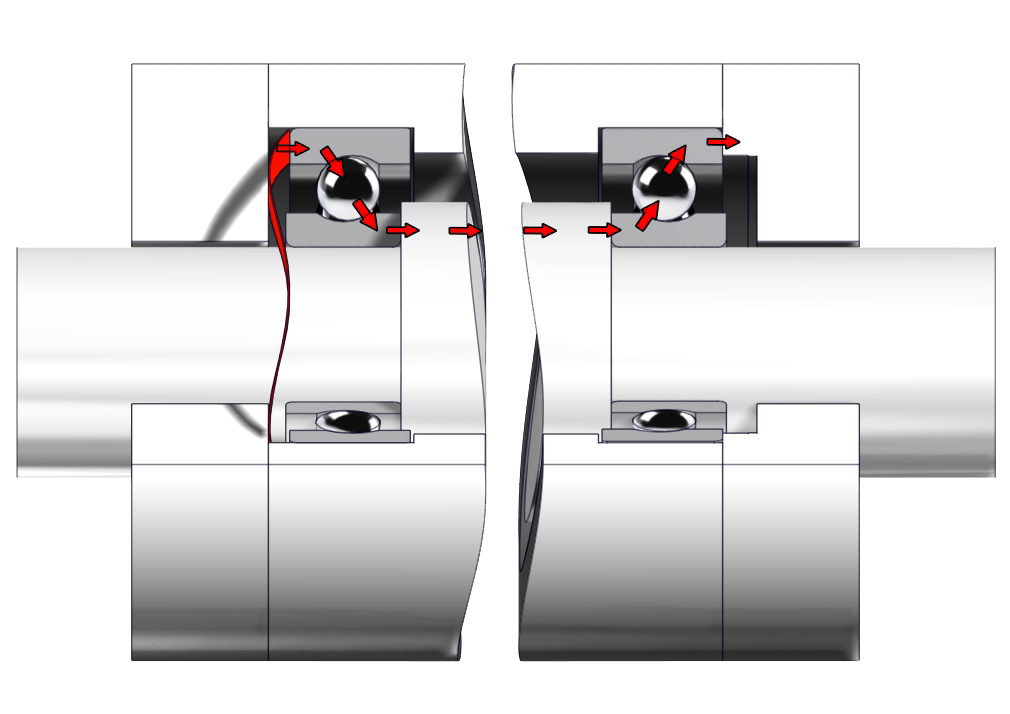

The internal clearance of the ball bearings is essential, but it generates noise and vibrations. Using wave washers to compensate for the internal clearance considerably reduces vibrations and thus, noise. This significantly increases the service life of the bearings.

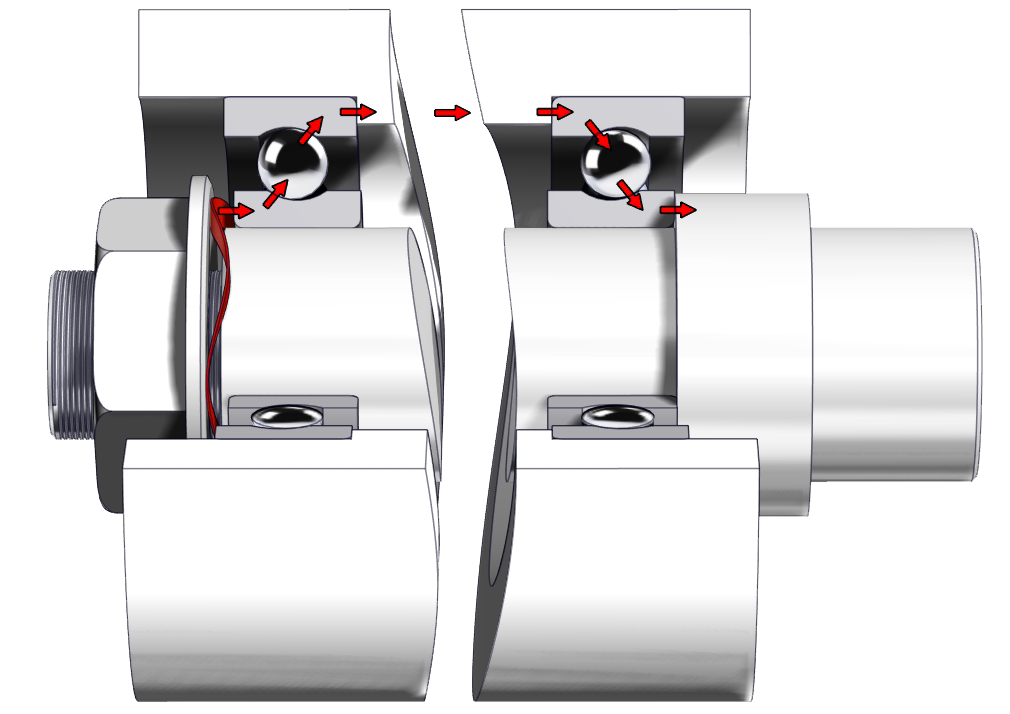

ROTATING OUTER RING:

the wave washer exerts pressure on the inner ring of the bearing.

ROTATING INNER RING:

the wave washer exerts pressure on the outer ring of the bearing.

Properly sized, the wave washer compensates for machining deviations, expansion gaps and ensures that the bearing always runs under the best conditions.

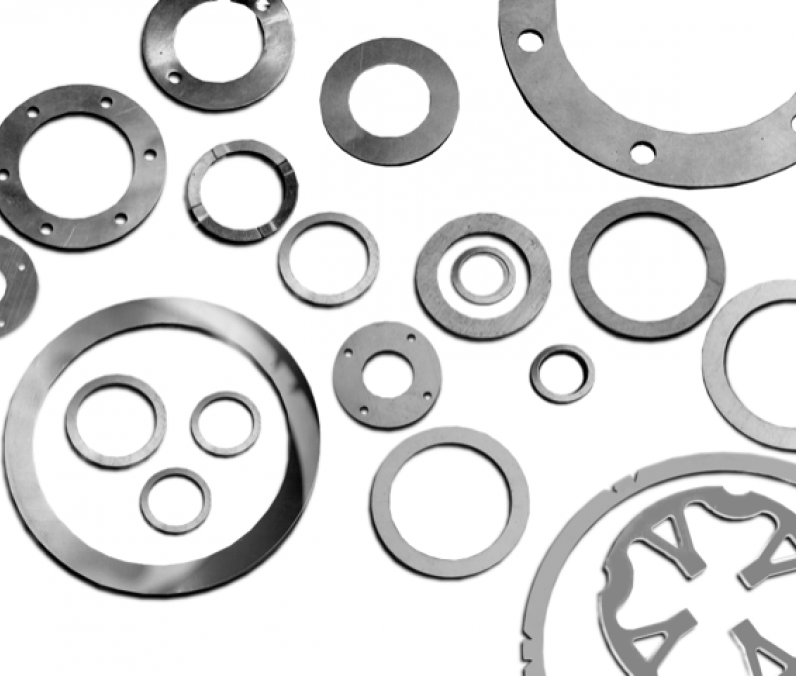

Borrelly offers two ranges of CN (Normal Clearance) C3 (Large Clearance) Wave Washers to preload bearings, one range for standard applications, and a precision range for aeronautical applications:

- Standard ranges CN and C3 C75s steel and 1.4310 stainless steel

- Precision ranges CN and C3 C75s steel and 1.4310 stainless steel

The differences between the ranges are as follows:

- CN and the C3 wave washers for standard applications are not calibrated under mounting heights; they are given for a free height and an approximate spring rate.

- CN and the C3 wave washers for aeronautical applications are calibrated under precise assembly heights and are checked before shipment using intensive sampling. Traceability is entirely managed by manufacturing lots using our QMS (Quality Management Systems) as per the ISO EN 9100 Aeronautics standard.

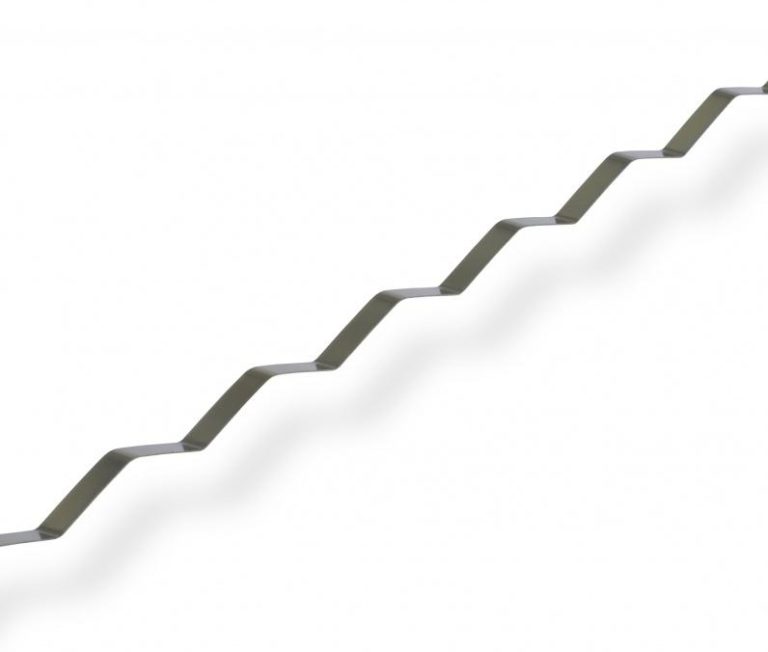

Like coiled wire springs (coil springs for example), wave washers are round elastic elements. In contrast to the former (which are “high” in relation to their diameter), wave washers are “low” in relation to their diameter.

Thus, wave washers are used when you want to insert a “round” spring element into an assembly and you have space along the diameter but not height-wise.

Wave washers can therefore be used for a wide range of applications other than to preload a ball bearing.

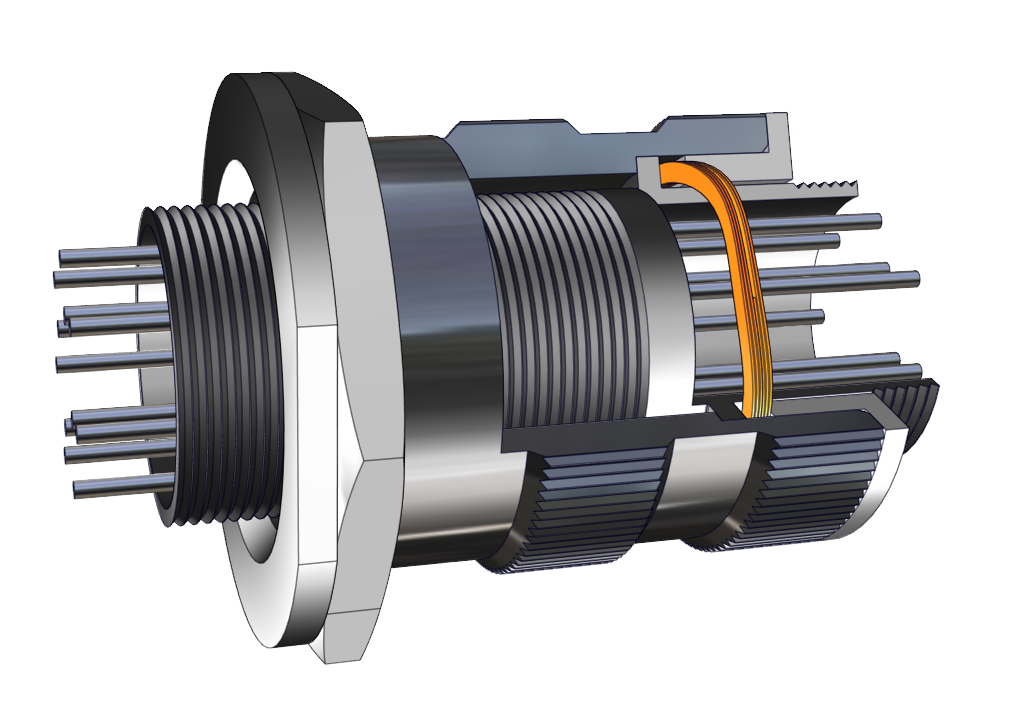

Multi-pin connector

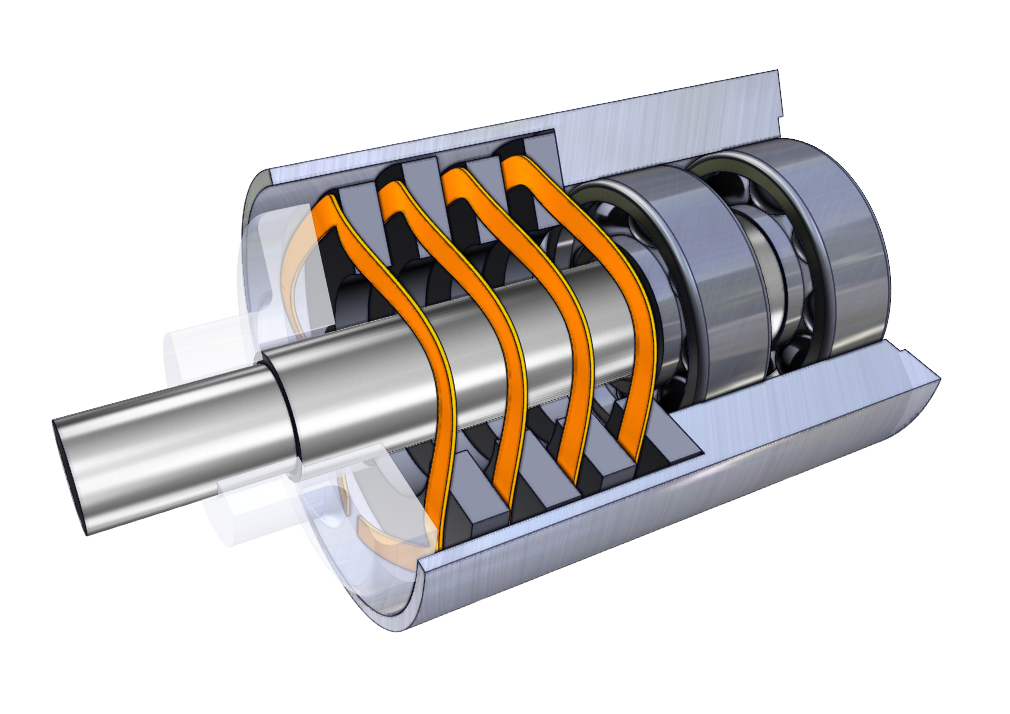

Clutch

With its extensive experience and technical expertise, Borrelly specializes in the design and manufacturing of wave washers that are specially customized for your most technical and severe applications.

99.8 %

Compliance

96 %

Reliability

48 h

Service