Retro-engineering

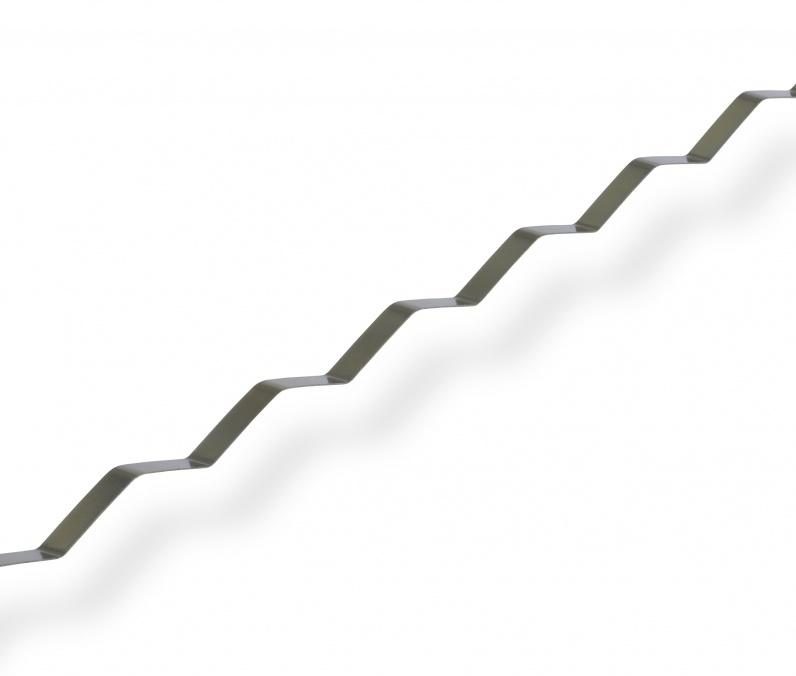

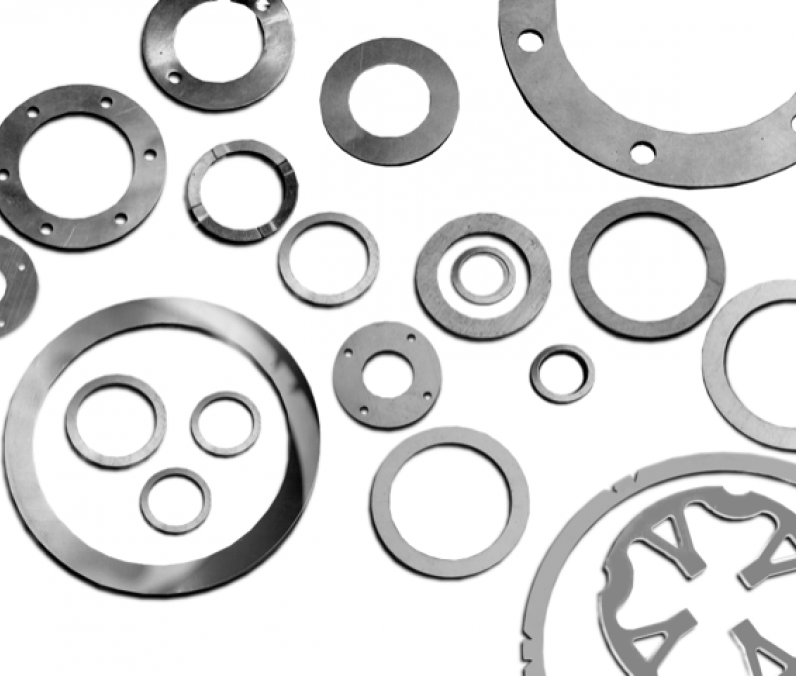

In a retro-engineering process, precision, material expertise, and a thorough understanding of the mechanical behavior of components are essential. This is where Borrelly comes in, offering robust, high-performance, and highly reliable solutions, the result of over 50 years of expertise in the design, manufacturing, and industrialization of custom-made spring washers.

Rely on our expertise to overcome your technical challenges

Whether dealing with a worn component, a part with missing technical documentation, or a system to optimize, our design office supports you at every stage of your project:

- Precise characterization of the original part: dimensional inspection, material analysis, mechanical behavior study.

- Digital reconstruction: 3D modelling, finite element calculations, simulation of behavior under static or dynamic loads.

- Technical recommendations: selection of the most suitable material from our extensive stock (carbon steel, stainless steel, superalloys, CuBe2, duplex, etc.), optimization of geometries and mechanical performance.

- Prototyping: in-house manufacturing, static and dynamic testing, fatigue testing.

Industrialization: development of a reliable and repeatable manufacturing process, rigorous quality control, full traceability.

Our team of engineers, equipped with proven simulation tools and design software, brings you in-depth expertise and excellent command of the most demanding environments: extreme temperatures, dynamic or static fatigue, limited space, etc.

We control all production stages in-house, from tool manufacturing to quality control, including stamping and heat treatment, all carried out at our workshops in Saint-Laurent-d’Agny.

Each Borrelly part benefits from full traceability, from material selection to shipping. Our processes, ISO 9001 and EN 9100 certified, rely on calibrated inspection equipment connected to the BNM, ensuring flawless compliance.

Borrelly, your trusted partner

Our in-house Engineering & Design Department can carry out all your retro-engineering projects with the following guarantees:

- Responsiveness in processing your analysis or re-manufacturing requests.

- In-depth understanding of the mechanical challenges associated with spring washers.

- The ability to supply parts individually or in series, in strict accordance with your specifications.

Our ability to deliver solutions and provide excellent manufacturing quality is recognized by key players across numerous sectors: aerospace, automotive, space, defense, nuclear, motorsport, mechanical industry, offshore, green energy, agricultural industry, renewable energy, medical, household appliances, and more.